With passion, precision, and purpose—we’re ready for what’s next.

- In der Au 2, 6341 Ebbs, Austria

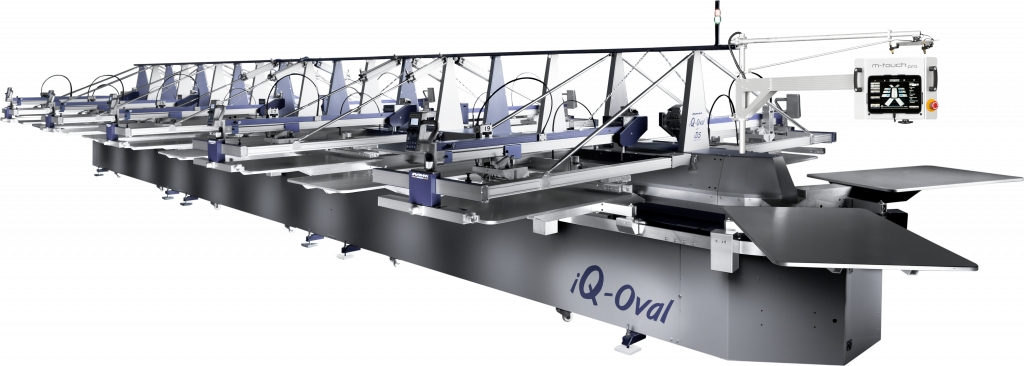

The iQ-Oval iDS redefines what safety means in screen printing. At its heart is the intelligent drive system (iDS), featuring independently driven tables that enable a truly groundbreaking safety concept. The machine instinctively senses resistance and stops immediately—protecting what matters most: your people.

The iDS intelligent drive system is the heart of the iQ-Oval iDS—and the reason it redefines what modern screen printing can be. Instead of relying on chains, belts, or bulky central drives, iDS uses independently driven pallet arms that move with absolute precision and control.

Power is distributed seamlessly around the machine via a circular rail, supplying each station individually. The result is fluid, high-speed movement that feels effortless—yet delivers outstanding accuracy down to the finest detail.

What truly sets iDS apart is its instinctive approach to safety. The system detects resistance in real time and stops immediately, dramatically reducing potential hazards. By limiting force to a single drive, operator protection becomes inherent—making physical safety barriers unnecessary and creating an open, confident working environment.

iDS is designed not only for performance, but for efficiency and ease. Variable, bidirectional indexing adapts perfectly to different pallet sizes and products, while intelligent features like automatic skip mode keep production running smoothly—even during maintenance or special setups.

With its modular, service-friendly design and uncompromising precision, iDS delivers more than speed. It delivers trust, confidence, and total control—every shift, every print, every move.

Each pallet arm is powered by its own intelligent drive, allowing every movement to be controlled independently. This eliminates mechanical dependencies and delivers unparalleled precision, stability, and flexibility throughout the entire printing process.

Power is distributed through a circular rail that surrounds the machine, supplying each pallet individually. This design ensures consistent energy delivery, smooth operation, and maximum reliability—even at high production speeds.

By eliminating chains, belts, and central drive components, iDS reduces mechanical wear and maintenance requirements. The result is a cleaner, quieter, and more efficient drive system built for long-term reliability.

Index speed can be precisely adjusted and controlled in both directions. This allows the machine to adapt perfectly to different pallet sizes, garment types, and production demands—ensuring optimal flow and timing in every cycle.

iDS supports both single and double index movements, enabling smarter production layouts and faster takt times. This flexibility opens new possibilities for complex workflows without compromising accuracy.

The drive system continuously monitors resistance during operation. The moment an unexpected obstacle is detected, the system reacts instantly—preventing damage and protecting both operators and equipment.

In the event of a collision, only the force of the affected drive is applied. The machine stops immediately, dramatically reducing potential injury risks and setting a new benchmark for operator safety.

Thanks to its intelligent safety concept, iDS eliminates the need for physical safety barriers. Operators benefit from open, unrestricted access to the machine—without sacrificing safety.

Controlled, vibration-free movement in both directions ensures stable pallet positioning and exceptional register accuracy. Every motion feels fluid, predictable, and perfectly synchronized.

When stations are removed or temporarily unused—such as during maintenance—the system automatically skips empty positions. Production continues seamlessly, maintaining efficiency even in non-standard configurations.

With positioning accuracy of up to ±0.02 mm, iDS delivers outstanding registration results. This level of precision ensures consistent print quality across long production runs.

The absence of a central drive allows individual units to be removed quickly and safely. Maintenance becomes faster, downtime is reduced, and service work can be performed with greater confidence.